ABOUT US

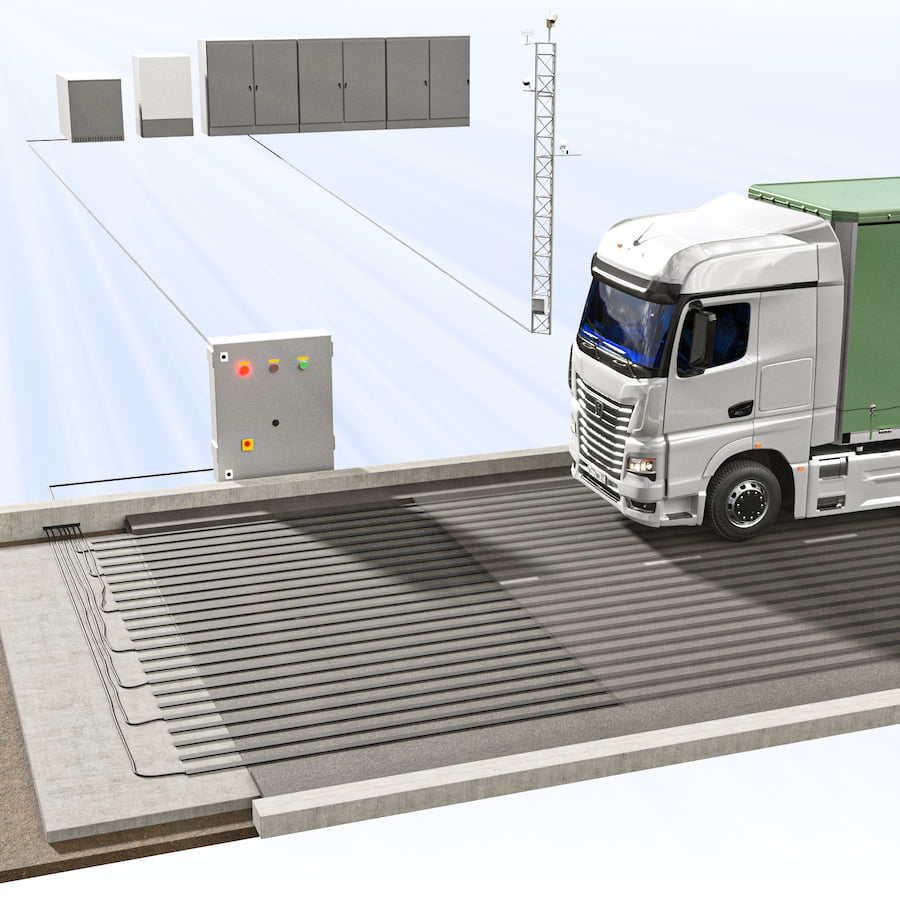

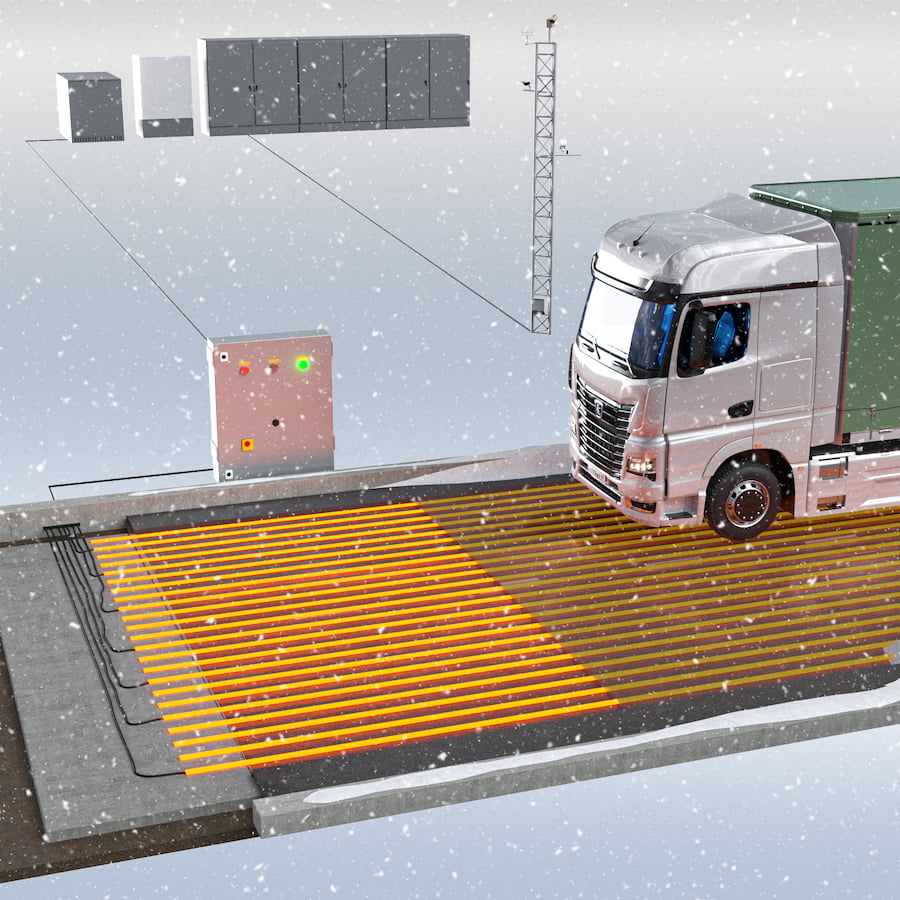

SNOWLESS is a real-time reactive, autonomous temperature control technology for climate-resilient infrastructure offering disruptive snow-melting/deicing, low temperature cracking prevention, and frost protection. Controlled by climate analysis algorithms, SNOWLESS guarantees superior energy efficiency.

HOW DOES IT WORK?

The SNOWLESS system is designed using a combination of patented hardware and software: Ultra robust amorphous alloy heating ribbons, embedded in the infrastructure top layer, and remotely controlled software based on real-time weather data, providing autonomous operation.

Receiving data

Detection of weather and surface conditions done by integrated sensors and local weather forecasts.

WHAT HEATING RIBBONS ARE?

A heating ribbon is a long flat element, with a nominally rectangular cross-section; it incorporates an internal metallic core that produces heat when an electric current is passed through it. By varying the input voltage, the actual heat output from a ribbon can be controlled to within the range of 0% to 100%. Overall, the ribbon can withstand temperature levels of up to 200°C during pavement construction operations.

INSTALLATION PROCESS

STEP 1 – Engineering

The SNOWLESS team will measure, plan and design the system on paper including an inspection visit to the site. A detailed electrical and deployment plan will be issued.

STEP 2 – Grooving

SNOWLESS technical team will arrive onsite to mark and groove the asphalt slits in which the heating elements will be placed in. The stage will be executed between asphalt layers.

STEP 3 – Deployment

The heating ribbons will be glued in the grooves using special bitumen for protection and fixation.

OUR COMPLETED PROJECTS

SNOWLESS systems were installed in multiple countries and applications, below are some examples.

-

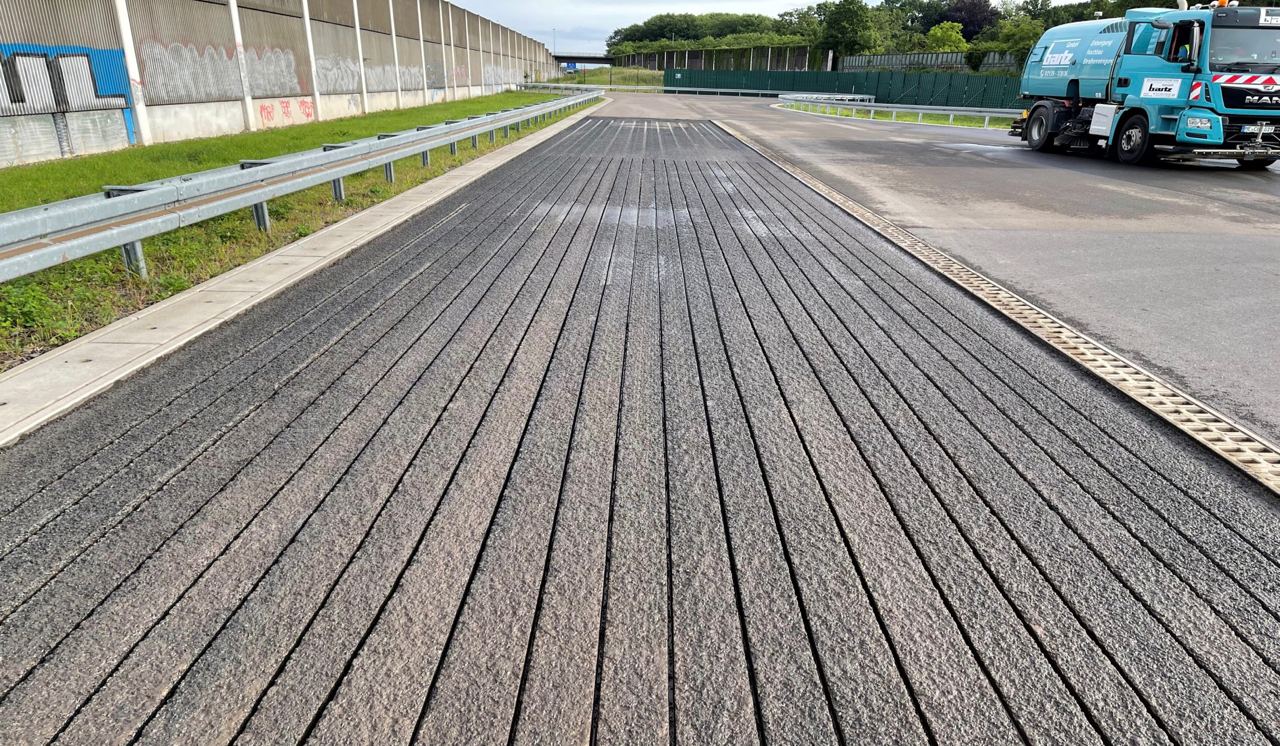

BASt Test Section

- Location: Germany

- Installation: 2022

- Application: Asphalt

- Heating Power: 210 KW

- Heated area: 2,000 m²

- Heating zones: 6 different heating zones

-

Maxima Hospital

- Location: Eindhoven, NL

- Installation: 2018

- Application: Asphalt

- Heated area: 700 m²

-

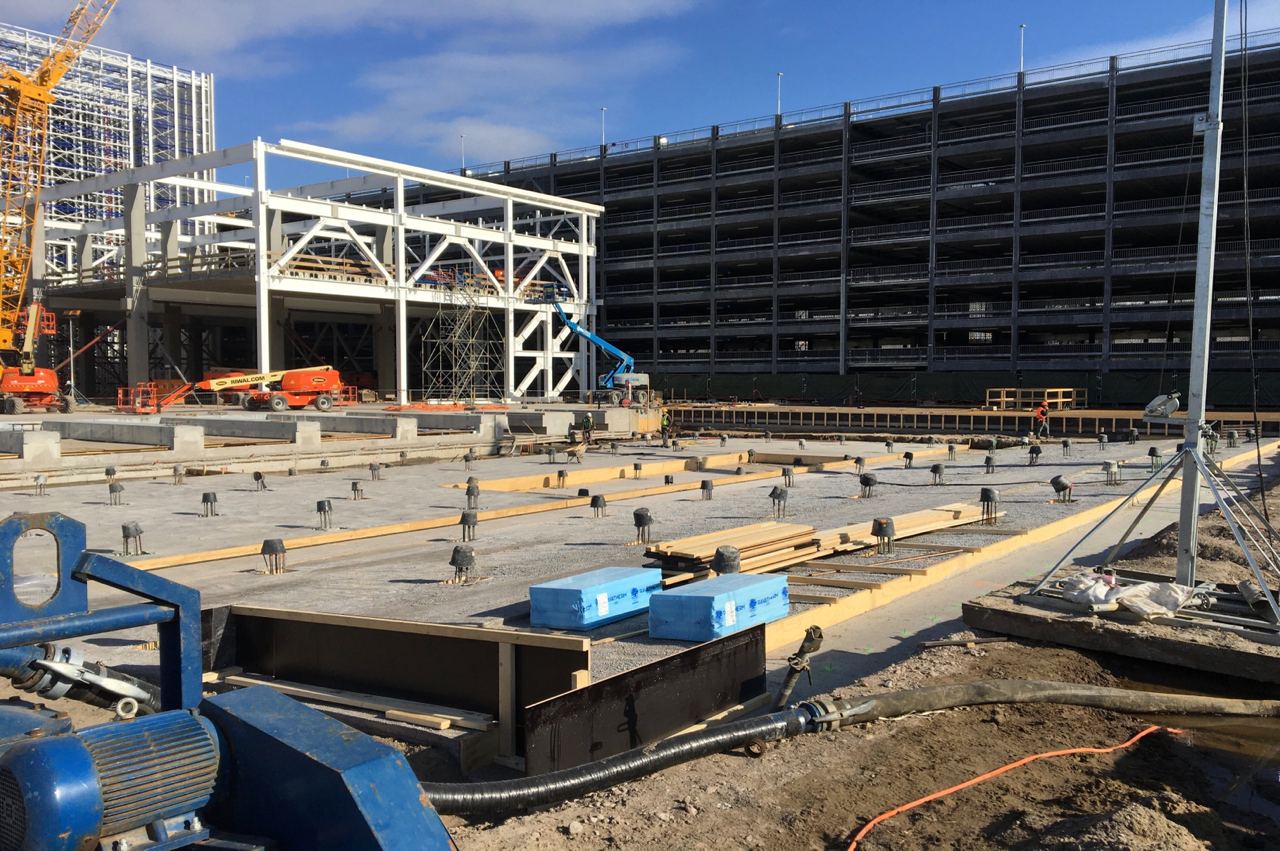

Truck Loading Dock

- Location: Eindhoven, NL

- Installation: 2020

- Application: Concrete

- Heating Power: 210 kW

- Heated area: 2,000 m²